2025

Onyx

A customized Apple Watch strap developed with Carbon DLS technology, featuring a parametric lattice structure that delivers both durability and superior comfort.

Fashion

Interaction design

Intro

Onyx is a customized Apple Watch strap developed with Carbon DLS technology, featuring a parametric lattice structure that delivers both durability and superior comfort.

My role in the project

As an Application Engineer Intern, I independently developed this watch strap project from exploration to validation. I worked hands-on with Carbon DLS printers and post-processing tools, and I personally printed and iterated on 200+ strap prototypes to refine geometry, lattice behavior, comfort, and manufacturability.

I collaborated closely with the materials team to understand elastomer performance and processing constraints, and with the business team to estimate production cost and evaluate commercialization feasibility. I also created and presented a pitch deck summarizing the technical learnings, user value, and business considerations.

Render Animation

How Might We?

The goal was to leverage Carbon DLS flexible materials and lattice design to create a smartwatch strap that balances breathability, comfort, and elastic recovery, exploring the potential of additively manufactured wearables.

Colors

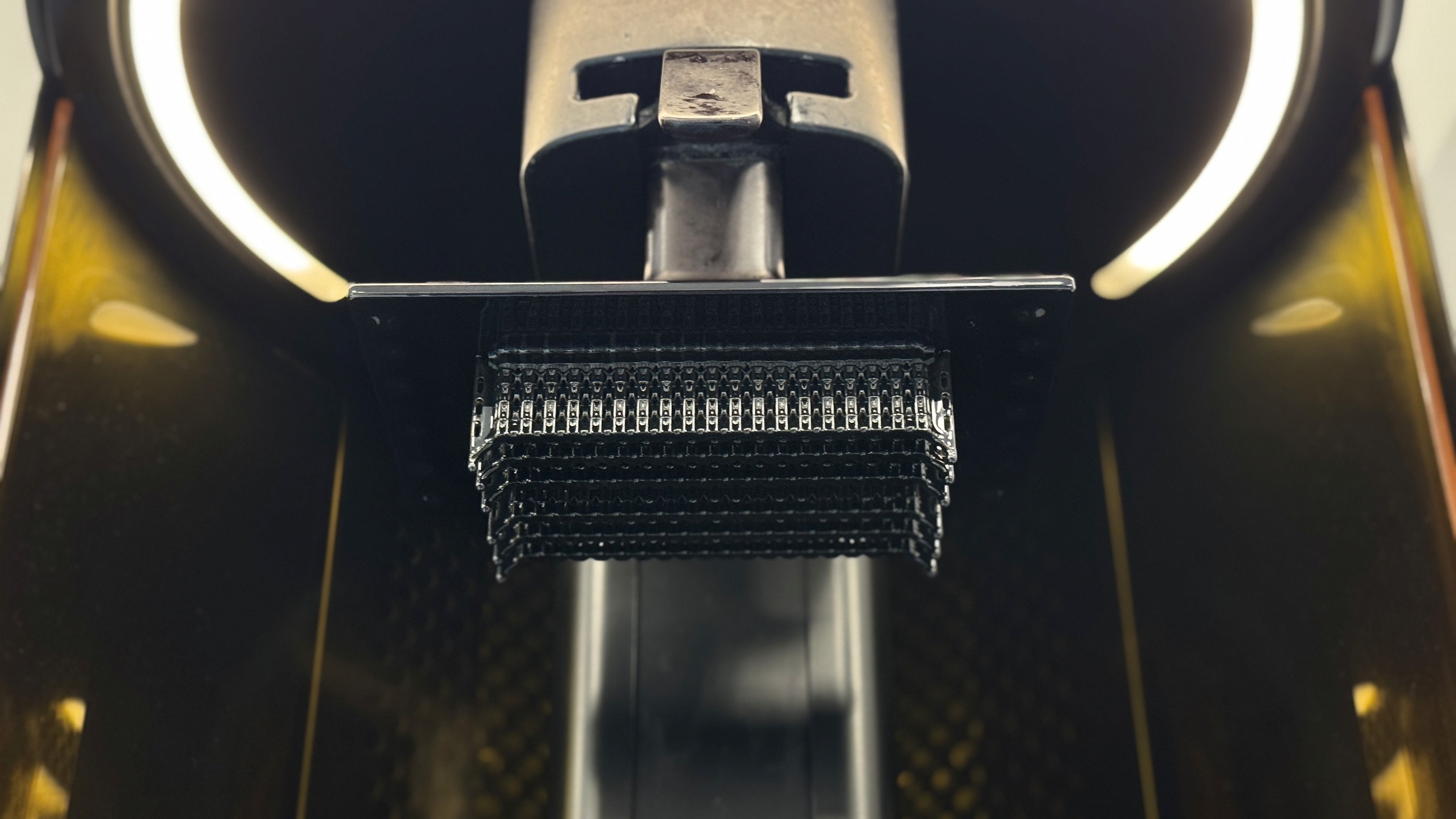

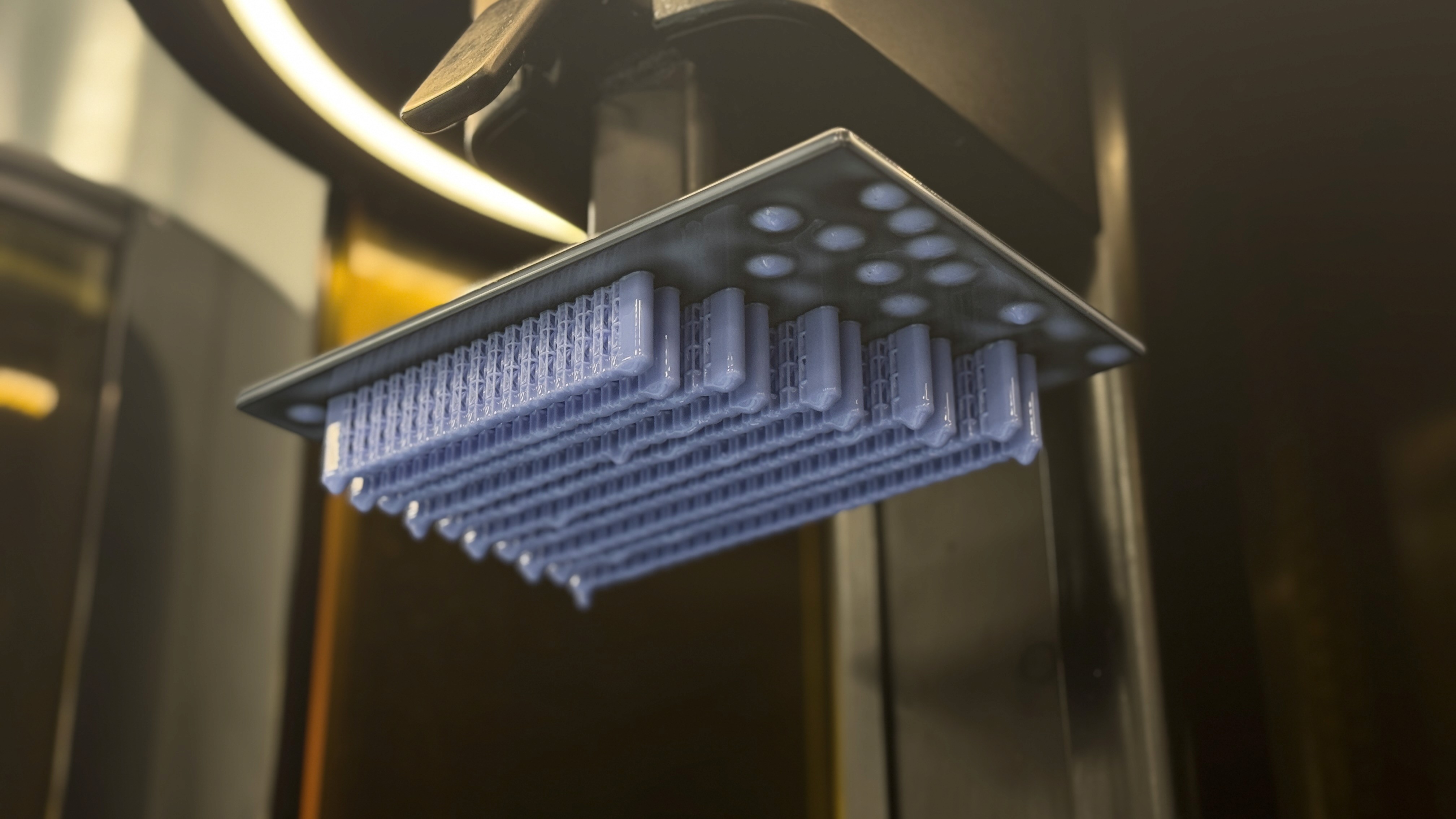

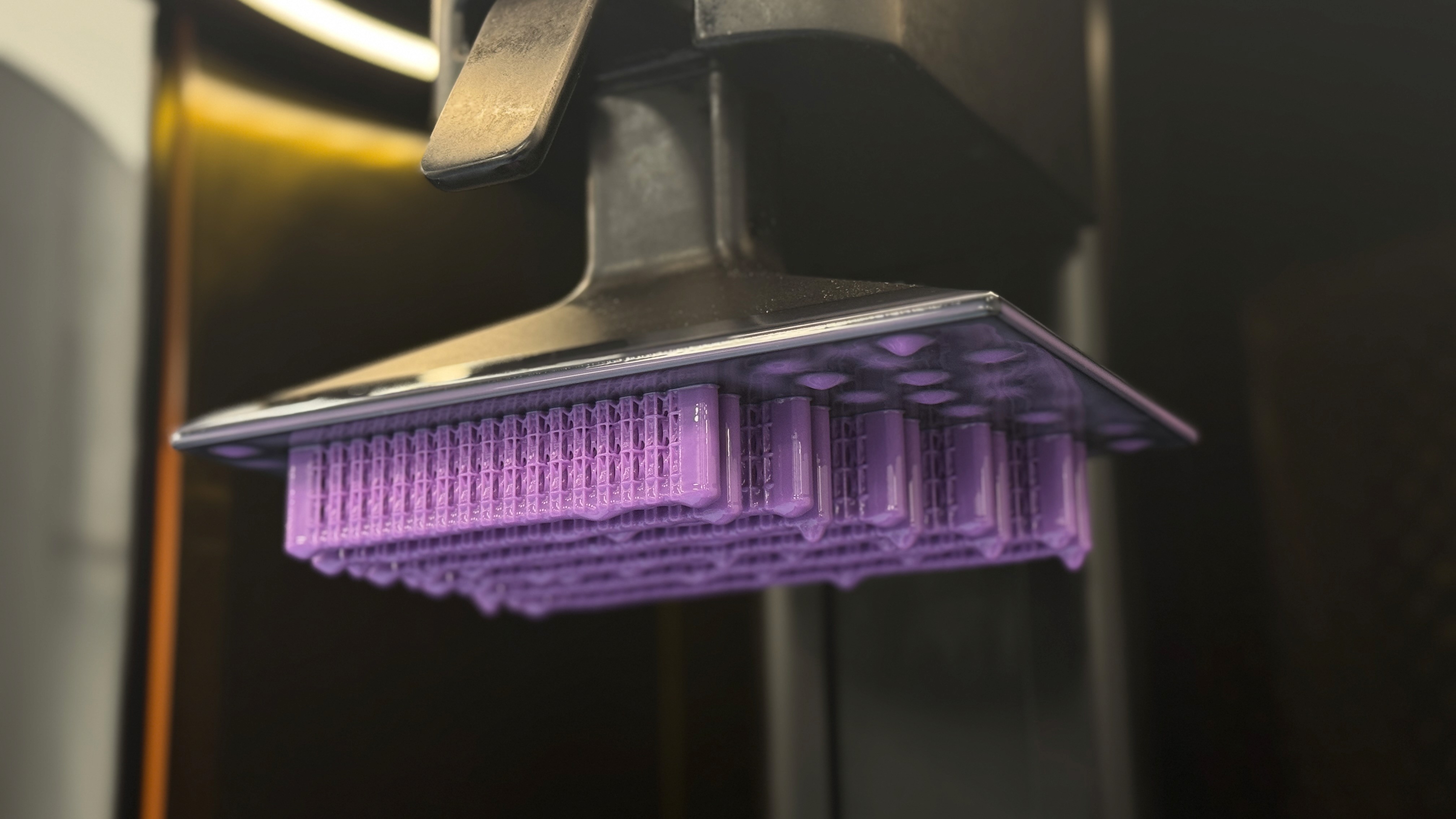

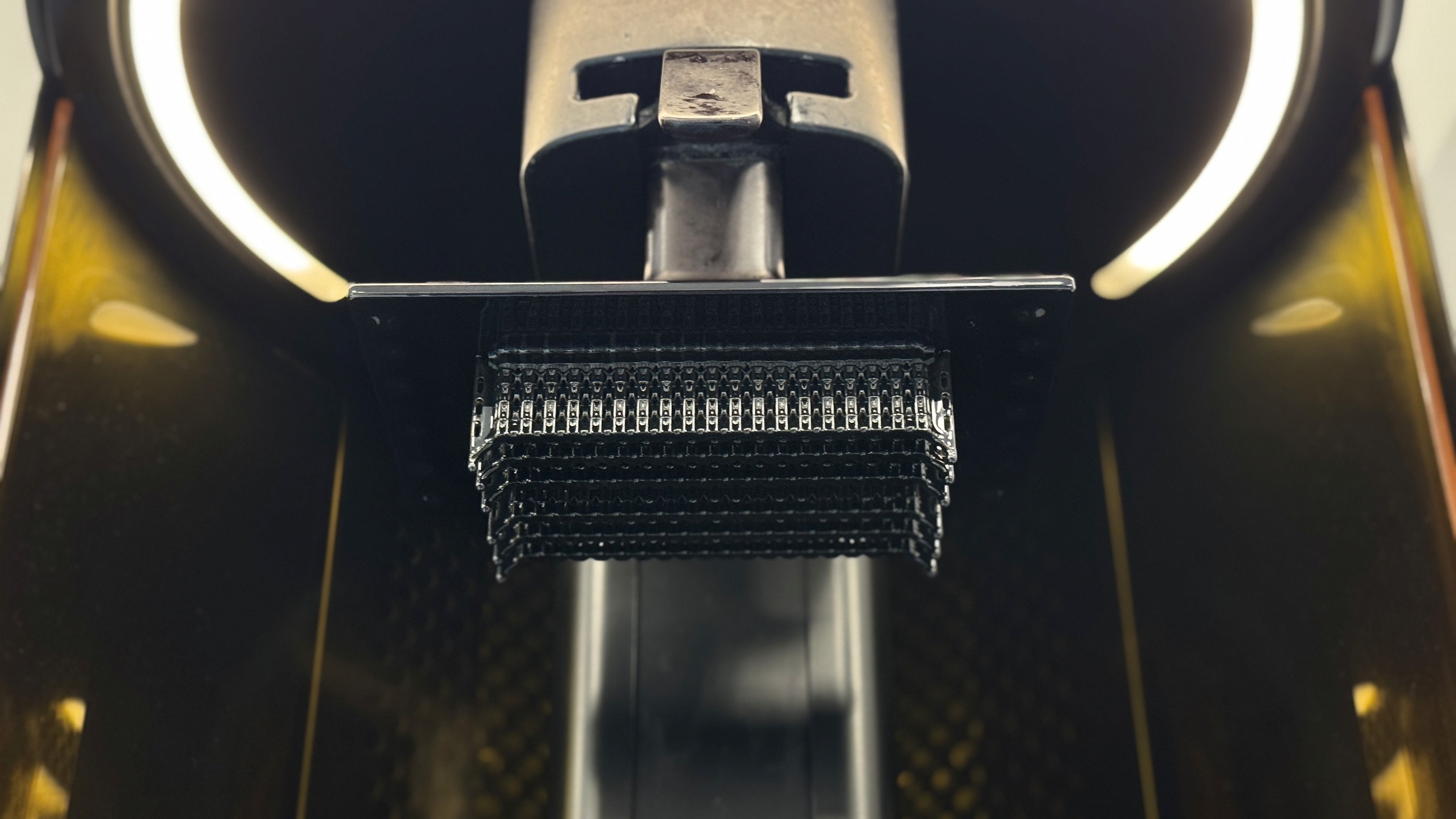

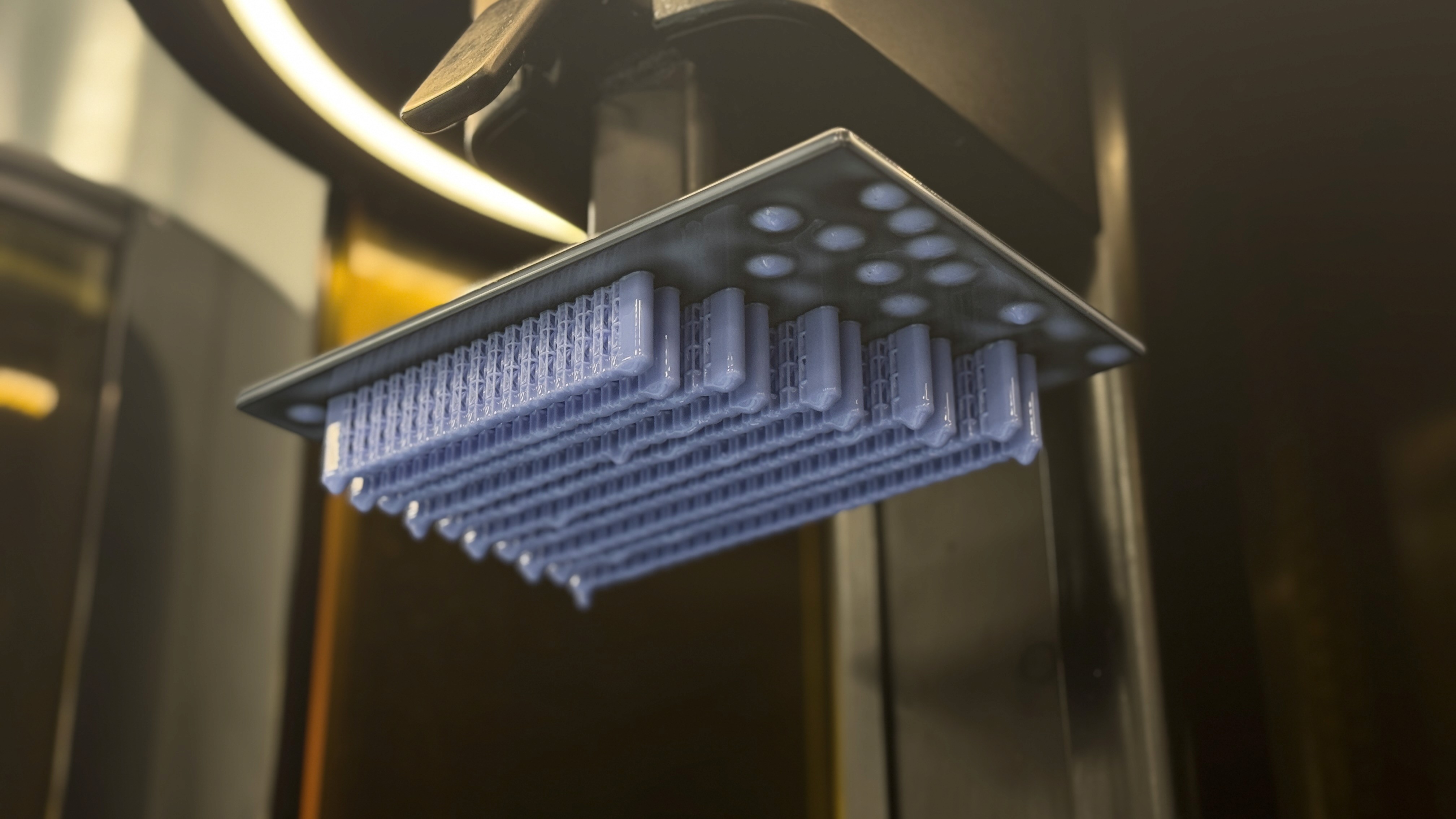

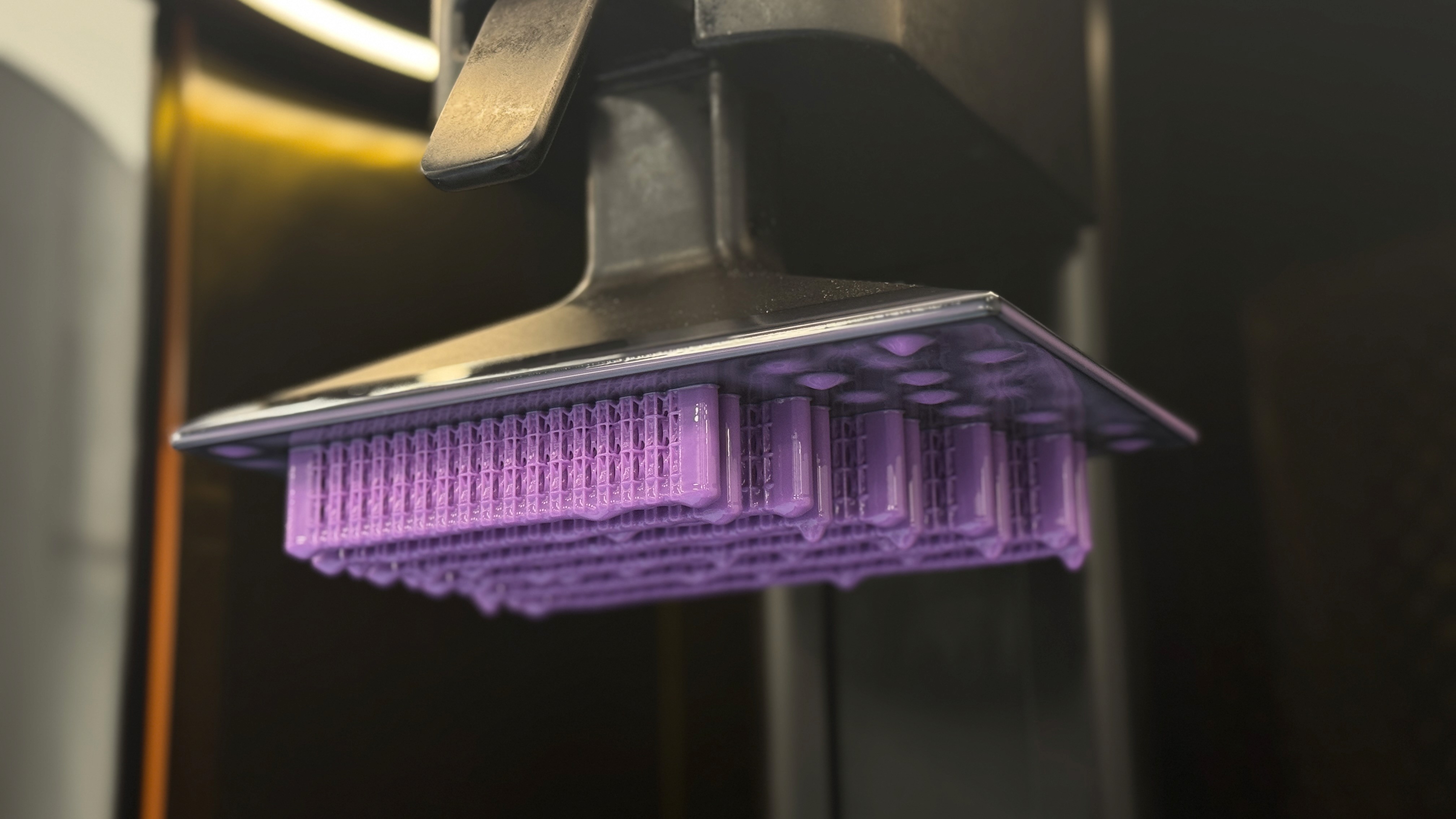

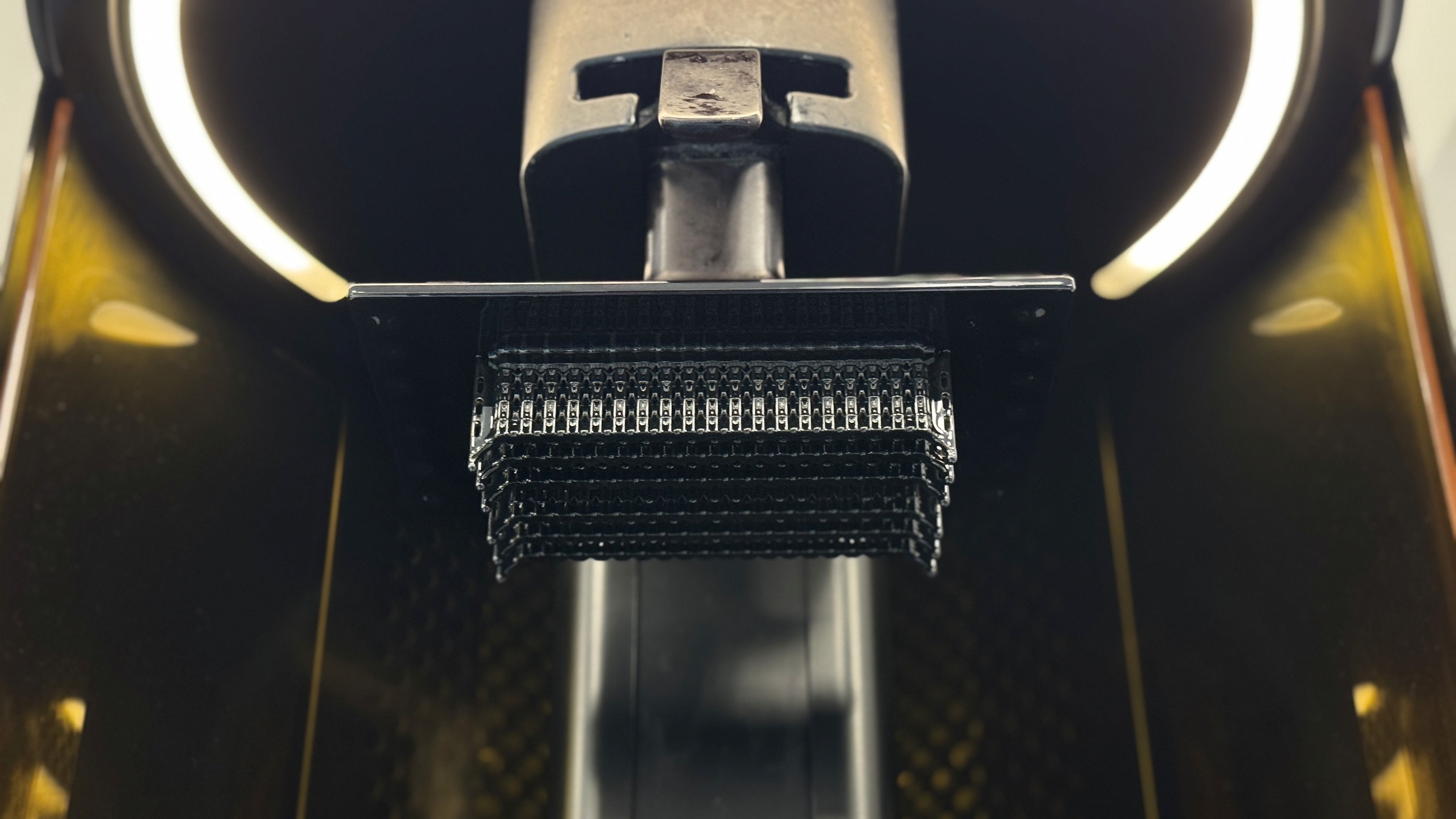

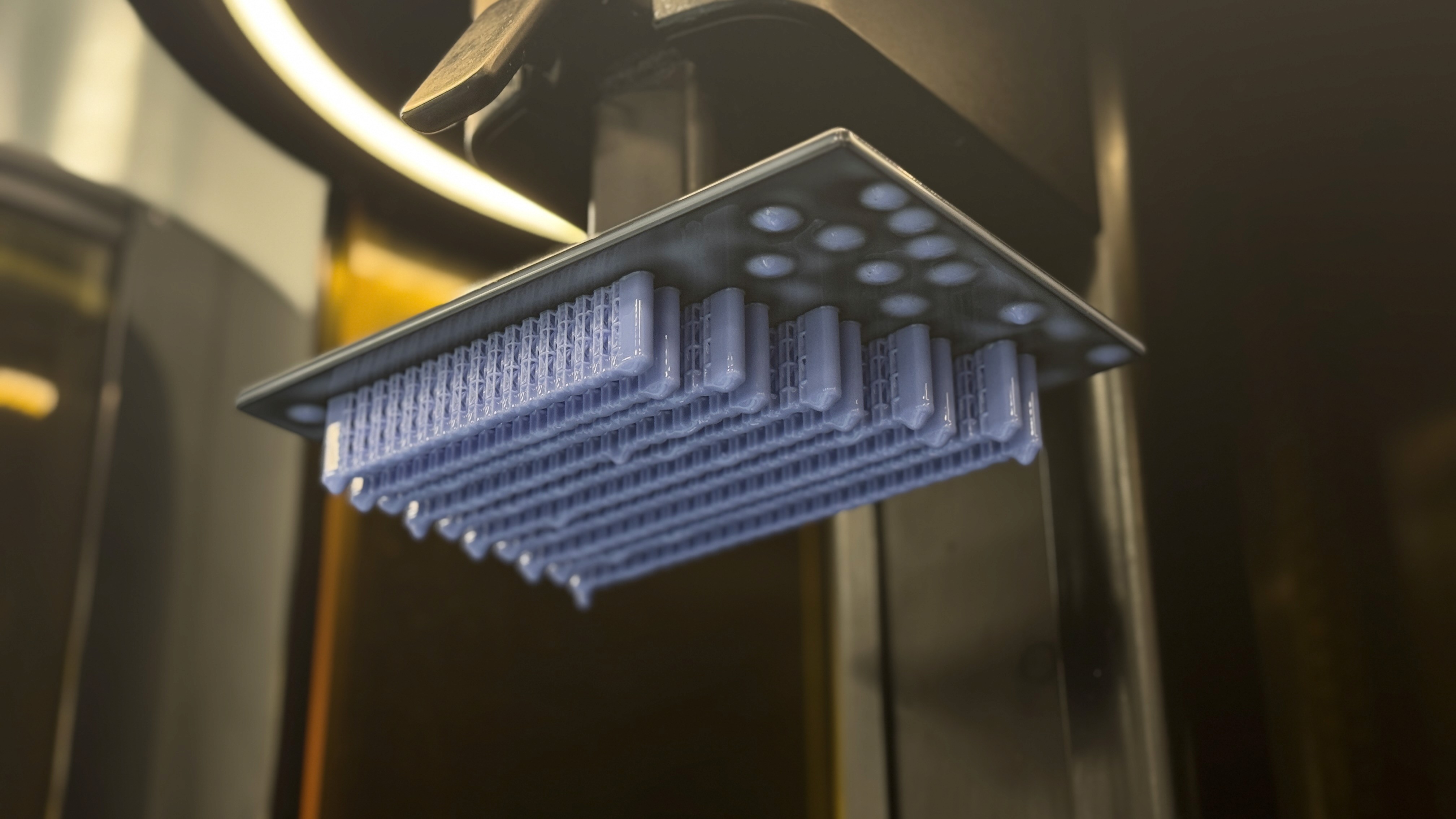

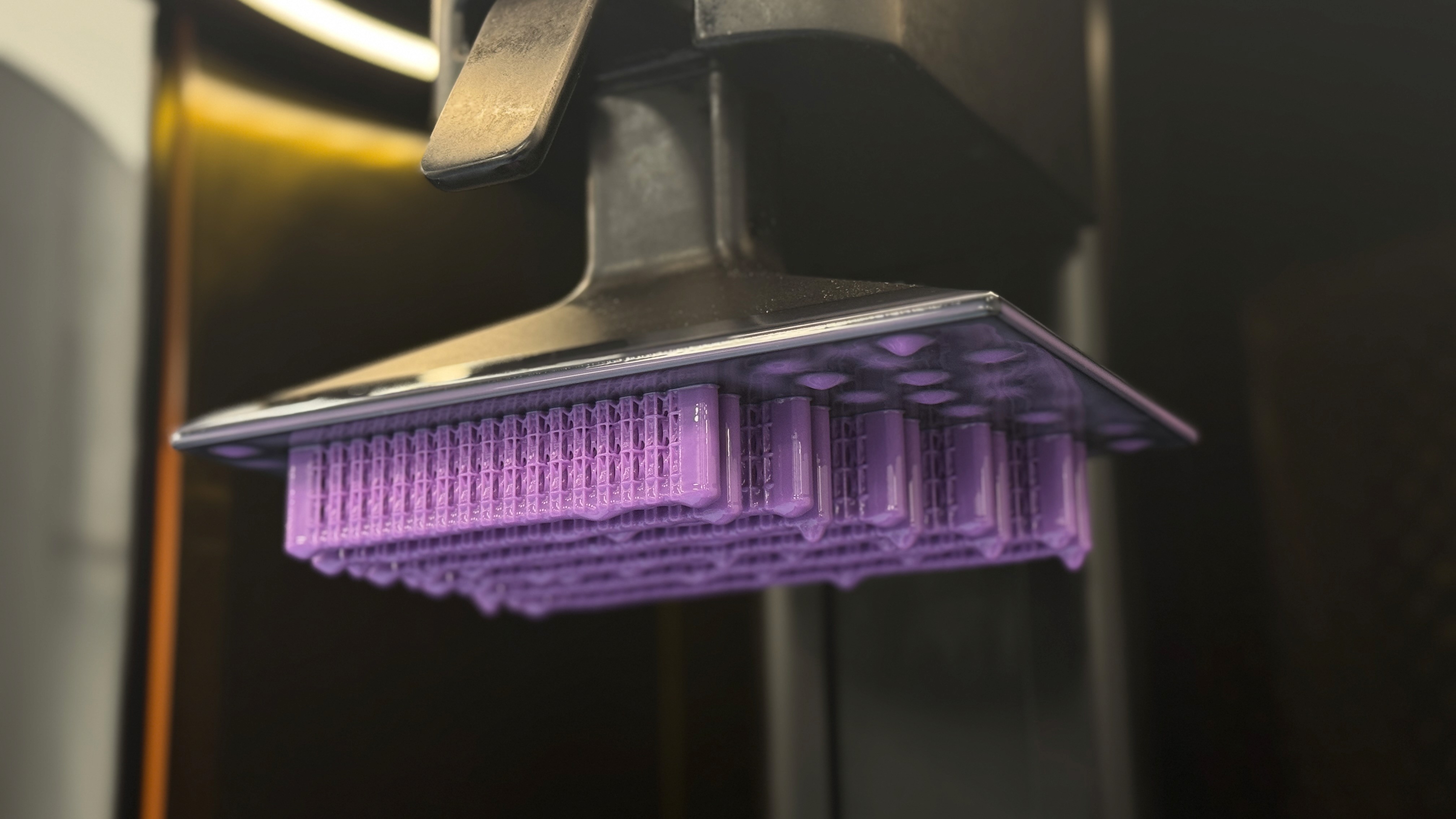

3D Printing

3D Printing

During material exploration, I tested three categories of elastomer resins commonly used in Carbon’s platform: including a soft flexible grade, a performance grade elastomer, and an expandable elastomer for post process dimensional tuning.

The performance grade elastomer emerged as the most viable option for production wearables due to its combination of elastic recovery, tensile stability, comfort, and consistent manufacturability.

Printed with colors

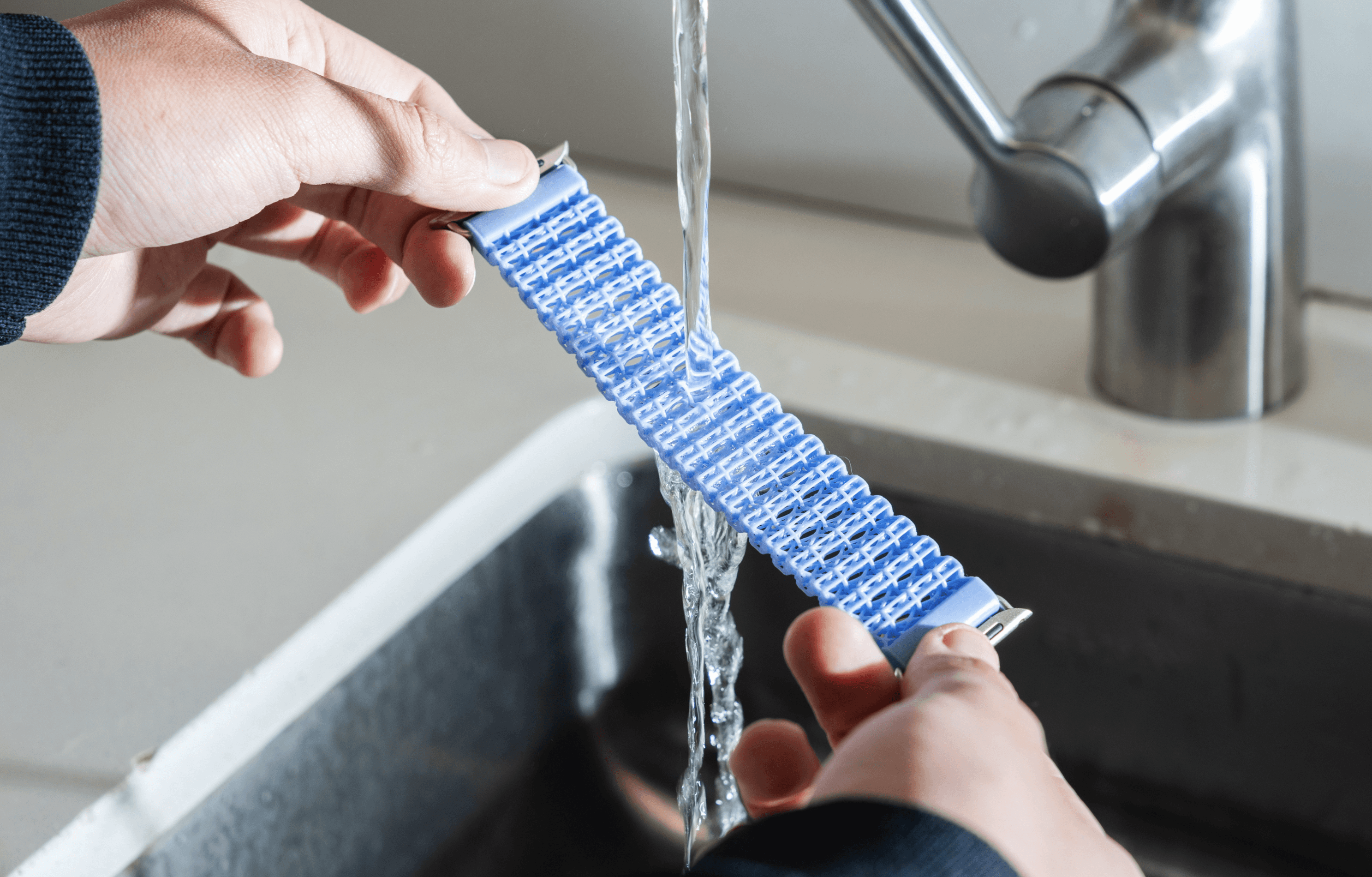

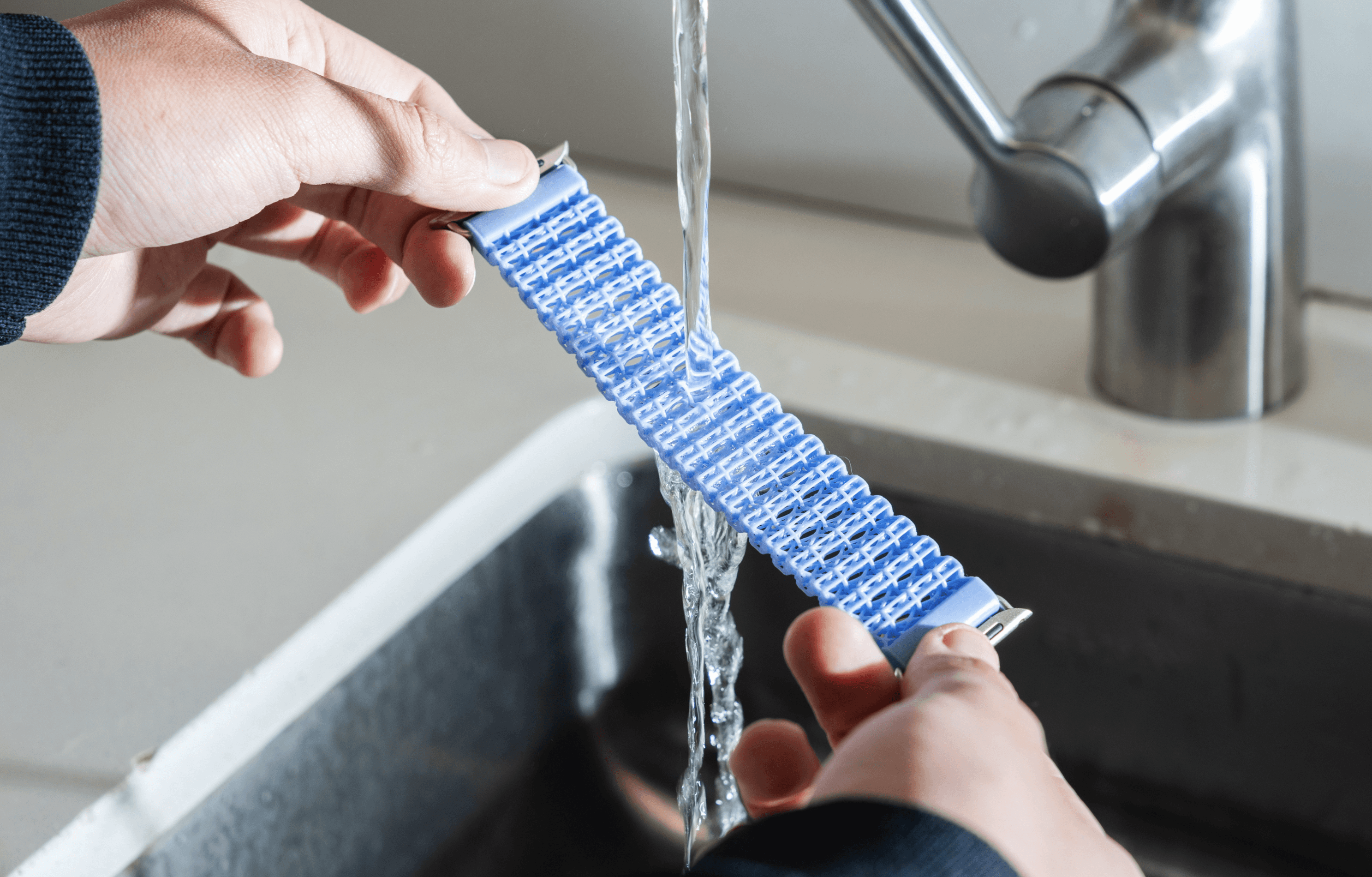

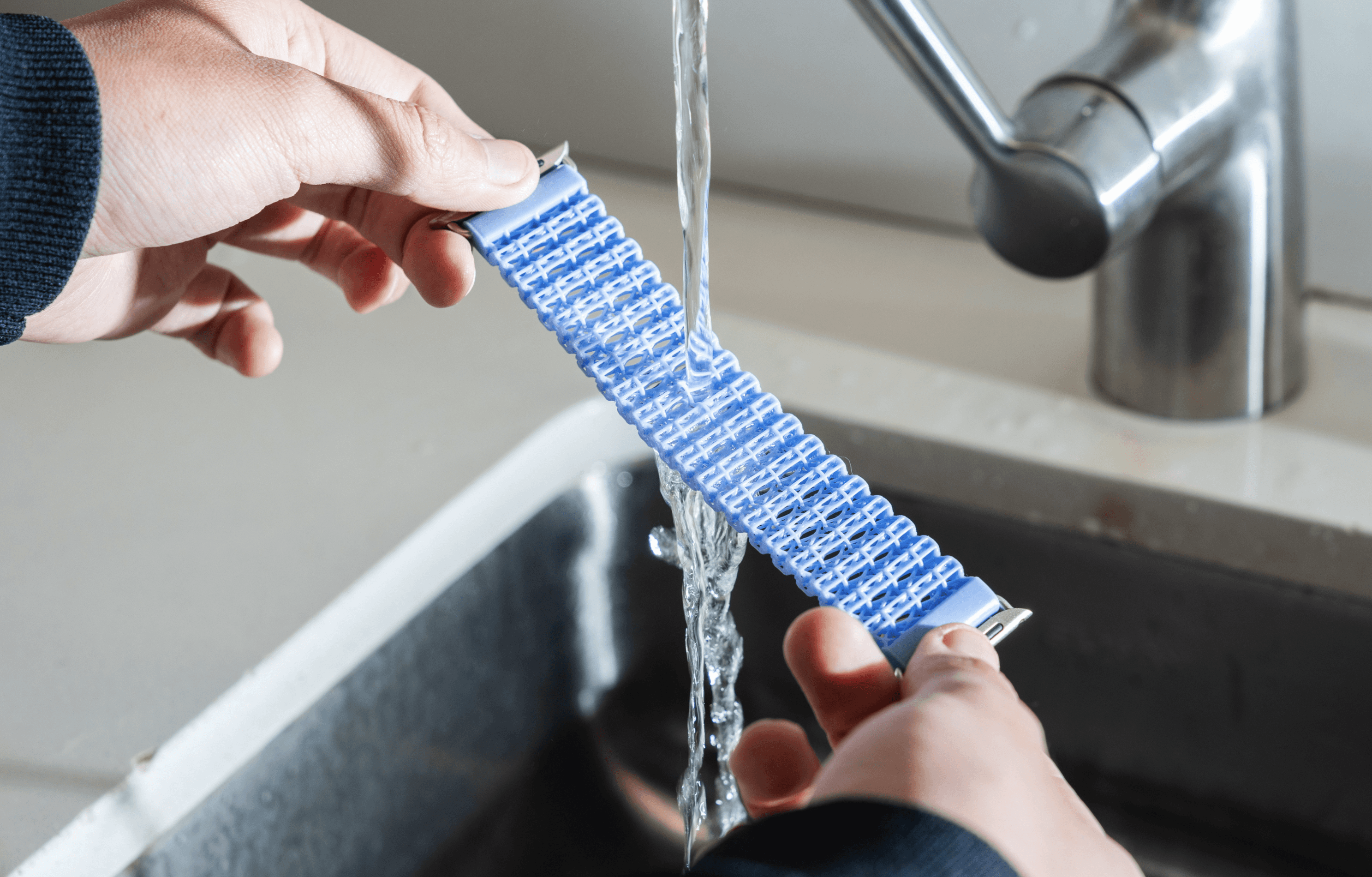

Photo

Tests

Mechanical Testing

✔ The selected elastomer showed strong elastic recovery

✔ Stable tensile behavior through the full processing workflow

✔ Comfortable skin contact performance

✔ Reliable dimensional recovery after curing and post-processing

I printed five strap specimens in different lengths and tested them on an Instron tensile machine

More Works

(GQ® — 02)

©2024

FAQ

01

What tools and technologies used in the project?

02

What is your inpiration?

03

How does the product stand out from the market? What is the result from compatible research?

04

What do you want to improve in the future?

2025

Onyx

Hi, I am Quinn® I’m a passionate and innovative 3D designer with over a decade of experience in the field. My journey began with a fascination.

Fashion

Interaction design

Intro

Onyx is a customized Apple Watch strap developed with Carbon DLS technology, featuring a parametric lattice structure that delivers both durability and superior comfort.

My role in the project

As an Application Engineer Intern, I independently developed this watch strap project from exploration to validation. I worked hands-on with Carbon DLS printers and post-processing tools, and I personally printed and iterated on 200+ strap prototypes to refine geometry, lattice behavior, comfort, and manufacturability.

I collaborated closely with the materials team to understand elastomer performance and processing constraints, and with the business team to estimate production cost and evaluate commercialization feasibility. I also created and presented a pitch deck summarizing the technical learnings, user value, and business considerations.

Render Animation

How Might We?

The goal was to leverage Carbon DLS flexible materials and lattice design to create a smartwatch strap that balances breathability, comfort, and elastic recovery, exploring the potential of additively manufactured wearables.

Colors

3D Printing

3D Printing

During material exploration, I tested three categories of elastomer resins commonly used in Carbon’s platform: including a soft flexible grade, a performance grade elastomer, and an expandable elastomer for post process dimensional tuning.

The performance grade elastomer emerged as the most viable option for production wearables due to its combination of elastic recovery, tensile stability, comfort, and consistent manufacturability.

Printed with colors

Photo

Tests

Mechanical Testing

✔ The selected elastomer showed strong elastic recovery

✔ Stable tensile behavior through the full processing workflow

✔ Comfortable skin contact performance

✔ Reliable dimensional recovery after curing and post-processing

I printed five strap specimens in different lengths and tested them on an Instron tensile machine

More Works

(GQ® — 02)

©2024

FAQ

01

What tools and technologies used in the project?

02

What is your inpiration?

03

How does the product stand out from the market? What is the result from compatible research?

04

What do you want to improve in the future?

2025

Onyx

Hi, I am Rosa® I’m a passionate and innovative 3D designer with over a decade of experience in the field. My journey began with a fascination.

Fashion

Interaction design

Intro

Onyx is a customized Apple Watch strap developed with Carbon DLS technology, featuring a parametric lattice structure that delivers both durability and superior comfort.

My role in the project

As an Application Engineer Intern, I independently developed this watch strap project from exploration to validation. I worked hands-on with Carbon DLS printers and post-processing tools, and I personally printed and iterated on 200+ strap prototypes to refine geometry, lattice behavior, comfort, and manufacturability.

I collaborated closely with the materials team to understand elastomer performance and processing constraints, and with the business team to estimate production cost and evaluate commercialization feasibility. I also created and presented a pitch deck summarizing the technical learnings, user value, and business considerations.

Render Animation

How Might We?

The goal was to leverage Carbon DLS flexible materials and lattice design to create a smartwatch strap that balances breathability, comfort, and elastic recovery, exploring the potential of additively manufactured wearables.

Colors

3D Printing

3D Printing

During material exploration, I tested three categories of elastomer resins commonly used in Carbon’s platform: including a soft flexible grade, a performance grade elastomer, and an expandable elastomer for post process dimensional tuning.

The performance grade elastomer emerged as the most viable option for production wearables due to its combination of elastic recovery, tensile stability, comfort, and consistent manufacturability.

Printed with colors

Photo

Tests

Mechanical Testing

✔ The selected elastomer showed strong elastic recovery

✔ Stable tensile behavior through the full processing workflow

✔ Comfortable skin contact performance

✔ Reliable dimensional recovery after curing and post-processing

I printed five strap specimens in different lengths and tested them on an Instron tensile machine

More Works

©2024

FAQ

What tools and technologies used in the project?

What is your inpiration?

How does the product stand out from the market? What is the result from compatible research?

What do you want to improve in the future?